Palletizing Robot Systems: The Key to Achieving Faster and Safer Production

Given that manufacturing and logistics today are evolving at a very rapid rate, companies are keen to seek these improvements and cuts. The one such solution is palletizing robot systems that involve using of robotics in palletizing and manipulating products. They are intended to address ever-increasing needs for speed, accuracy, and flexibility in various sectors such as food and beverages, pharmacy and drug, retail and mail order, automotive, and manufacturing among others.

What are Palletizing Robot Systems?

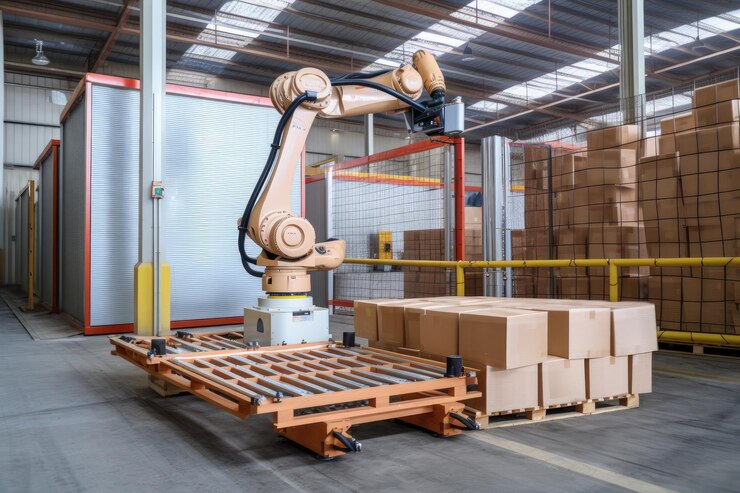

Palletizing robot systems primarily incorporate industrial robots to package products on pallets in storage or for transportation purposes. These systems increase the application of robotics in warehouses, minimize the use of labor, and also increase production. By creating value from a simple palletizing machine to an automatic palletizing system, the use of automatic palletizing has become highly desirable given the rise in e-commerce and international trade.

Advantages of the Palletizing Robots Systems

This article will explain how robotic systems have so many advantages that, once adopted ecosystems, contribute positively to the constant optimization of production lines. Below are the key advantages of adopting palletizing robots in your warehouse or manufacturing facility:

Increase Warehouse Efficiency

Automated palletizing systems enhance the level of automation in warehouses dramatically. Such systems reduce human interference and may work at any time making productivity high and operation seamless in busier places. This is especially useful for specialists dealing with palletizing e-commerce orders or other industries requiring fast product handling.

Improve Production Output

Robots work at a faster rate than human workers do, thus, a robot is likely to move more pallets in an hour or a day. This results in enhanced production capacity and ensures that business organizations meet increased demand rates, particularly within high-speed palletizing operations.

Reduce Labor Costs

The other major benefit of automated palletizing is that it eliminates most of the labor costs. Palletizing robots can reduce time-consumptive motions so that employees can concentrate on more complicated processes. This is especially helpful where labor is scarce or is expensive to avail like in countries with lean employment rates.

Enhance Product Safety

Robotic palletizing reduces cases of human interference and mistakes with the process. Robots help in packing to order and hence minimize damages that can occur to goods in the course of transportation and/or storage. This results in improved product safety whereby in industries such as pharmaceutical palletizing, the product’s safety or functionality is important.

Elements of a Palletizing Robot System

A well-designed palletizing system consists of several key components that work together to ensure efficient operation:

End-of-Arm Tooling (EOAT)

However, EODT is the part that is mounted to the arm of the robot and comes in contact with the product. It is intended for use to facilitate a particular kind of load that is being palletized, such as a box, bag, or container. The basic EOAT design may not be sufficient although it is usually recommended by the company; thus, a new EOAT design is developed depending on the industry or type of product.

Vision System for Palletizing

Numerous current palletizing robots include visioning systems that allow the robot to recognize merchandise. These systems play the role of navigation to the robot and facilitate accurate positioning of the merchandise on the pallet. Vision-guided palletizing is particularly advantageous in e-commerce order fulfillment robots thus order fulfillment robots containing products with sizes and different shapes and sizes can benefit from this technique.

Palletizing Software

Palletizing software is used extensively to control and coordinate the overall system. It also interfaces with other WMS and includes information about the robot’s operations in real-time. This guarantees that the palletizing process receives optimum flow and the system can be readjusted for varied levels of operational throughput.

Choice Criteria for Selecting a Palletizing Robot System

Selecting the most appropriate palletizing robot systems are very big decision. Here are some factors to consider:

Speed and Efficiency: In particular, the use of high-speed systems is most appropriate for the production of palletizing, for example, for e-commerce or the food and beverage industry.

Payload Capacity: Depending on the type of products that are packed, you may need high payload palletizing robots since some products may require handling throughout the production line.

Scalability: The system should expand its wealth continually in response to the growth and rising demand in the future.

Integration: Ensure that the palletizing system will work hand in hand with your current warehousing robotic system and logistics robotic system.

The Role of Vision-Guided Palletizing Robot Systems in Modern Manufacturing

Integrated palletizing robotic systems are fast becoming a reality in today’s production lines through vision-guided technologies affording better accuracy and productivity. These advanced robots utilize vision cameras and the concepts of artificial intelligence localization to recognize products and place them appropriately on pallets minimizing errors and operational time. In food and beverage, automotive, or e-companies, for instance, vision-guided robotics helps to increase efficiency when packaging and reduce downtime. Thus, they can allow real-time visual feedback to lessen restrictions in regard to the product type and size and enhance the flexibility of the systems and the productivity rate. Learn how the vision-guided palletizing robots improve the general flow of production processes and increase revenue.

Why Choose Warsonco Robotics?

We have more than ten years of experience in Robotics Development for home, industrial and commercial use. Warsonco Robotics has a great advantage in the company with years of experience in designing innovative technological solutions for automation. As evidenced by our having successfully installed automation products for more than 40 million users globally, we boast of being the most successful in helping industries worldwide.

Capability

Warsonco has the most flexibility option on robotics which includes high-end technology solutions in different sectors. Our understanding of the working of processes in industries allows us to develop efficient models of robots that help in decreasing operational costs and increasing productivity.

Customized Service

You need to understand that every business is different, and as such it needs to be handled differently. That is why; at Warsonco Robotics everything the packaging of your products is fully flexible to your individual needs. This makes it easy for us to fine-tune our systems to match your specific requirements of operation therefore achieving integration and efficiency.

ROI Benefit

The benefits accruable from the implementation of our automatic systems are a phenomenal ROI. Our product offering is particularly flexible to manufacture, therefore expecting investors to get their ROI within 0.5-1 years, which makes us the perfect choice to increase the company’s profitability.

Serve

Thank You for visiting Warsonco: Our primary goal is to make you satisfied. We operate a 24/7/365 Service First support line and offer lifetime support on all of our products. Our committed team helps to maintain your systems to perform optimally, thus reducing downtimes. Customers should contact Warsonco Robotics for Professional, customized, and cost-effective Robotic Services.

Conclusion

Palletizing robot systems are transforming industries by offering speed, precision, and cost efficiency. Whether you’re in food and beverage palletizing, pharmaceutical palletizing, automotive palletizing, or e-commerce palletizing, robotic systems provide the scalability and flexibility required to meet today’s demands. For more information on automated palletizing solutions, visit Warsonco.