The Ultimate Guide to Palletizing Robot Price for Small and Large Businesses

Robotics in warehouses and distribution centers/ factories has transformed industries in different parts of the world. Among these, the palletizing robot plays a significant role in having led to greater efficiency, lesser cost of hiring people, and most importantly enhanced productivity. This article will examine the palletizing robot price in relation to other markets and the factors that have an impact on its price. This guide will guide you on whether to invest in an industrial robot palletizer for your business whether big or small operation comes with certain costs.

What is a Palletizing Robot?

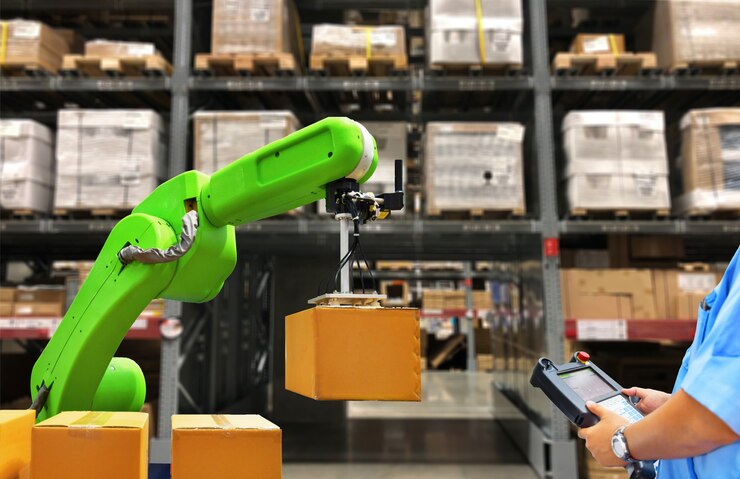

A palletizing robot is a kind of industrial robotic system that is used to pile the products and adjust their positions on the pallets. This type of robotic application is most common in the packaging, logistics, and material handling industry where there is a need to process large numbers of products stacking and sorting. Robotic automation in particular, plus industrial automation as a whole is making palletizing robots an attractive means of solving particular problems at different companies.

Factors Affecting Palletizing Robot Price

There are several parameters that influence the price of Palletizing Robots as explained below;

Type of Robot

Palletizing robots are of different classifications depending on the particular uses assigned to them. The main types include:

• Delta robots: These are suitable for high-speed, lightweight operations normally found in applications in the food and packaging businesses. Their price usually ranges from moderate to low priced though they are built for accuracy.

• SCARA robots: These robots are for a horizontal pattern and are used for activities that need more flexibility and speed. The SCARA robot palletizer price is relatively moderate compared to the other uses of this robot model.

• 6-axis robots: Being general utility robots, 6-axis robots have noted high flexibility and are thus suitable for intricate palletizing applications. Commonly, the 6-axis robot palletizer price is higher than the other palletizers because they possess great performance features.

Automation Level

A considerable influence on the price is the level of automation of the production process. A complete automatic palletizing system will cost more than the one system that has some human interference. Yet with such advantages as lowered labor costs, increased capacity, improving automated systems are worth every penny.

Load Capacity and Speed

The cost of the palletizing robot depends on the ability of the robot to handle different weights and volumes of the material to be palletized. Here, we have found that robots with more payload capacity and robots with shorter cycle times are more costly. For instance, an industrial robot palletizer meant for use in the industrial area, which is bulky and strong enough to handle larger amounts of workloads will cost more than a light industrial robot palletizer.

Customized Solutions and Interface

Added accessories such as vision systems, specific grippers, or interphase compatibility from a current WMS will also raise the robotic palletizer cost. If the business wants a custom solution the costs of these integrations should be factored in.

How Much Does a Palletizing Robot Cost?

The above factors will determine the exact palletizing robot price and it is clear that it is not standardized. It can take on average $20000 to $250000.

Palletizing Robot Price for Small Businesses

If the prices are to be looked at in terms of affordability, especially for small businesses or startups, then a palletizing robot will cost you a slightly lower price. New palletizing robots cost for small businesses falls between $20,000 and $50,000. While such systems are normally not as complex and packed with options as the existing ones, they provide significant performance increases at a price of requiring less manual input. If there are specific details concerning the palletizing robot price, the cost depends on the type of robot, the degree of automation, the load-bearing capacity, and location. If you’re seeking a small business robot or stronger features for large Enterprises, you have to consider the needs and the expenses accurately.

Versatile and Relatively Affordable Palletizing Robot by Warsonco

A versatile and relatively affordable palletizing robot is compatible with your current systems and provides excellent positioning while being operationally simple, thus fitting a wide range of organizations. This means that when you purchase the right robotic palletizer, you will get benefits like low charges for labor, the highest levels of productivity, and efficiency in the production job. Warsonco Robotics is your reliable source of palletizing robots in this regard. We provide solutions that are affordable, easily compatible, and expected to provide high accuracy in positioning your operations. If you are just a new user or expanding, our robots are very easy to implement and run. To know more about the palletizing robot price and find out how our latest robotic technologies can benefit your operations, go to Warsonco Robotics.

Palletizing Robot Cost for Large Business Industry

Smaller businesses will find the prices somewhat reasonable, especially when considering the fact those larger companies that need systems with high speeds and overall higher capacities will have to pay much more. The palletizing robot cost the costliest can go as low as $100,000 for local large businesses and extend to $250,000 on the need of specifications and level of automation that might be required by a business. These systems are mainly implemented in wide Warehouses and factories where there is so much cutthroat congestion thus requiring a high rate of movement.

The Advantages of Adopting the Palletizing Robot

Although the palletizing robot cost may seem high at first, the benefits make it a worthwhile investment for many businesses:

• Increased Efficiency: Reliability: Robots are able to perform tasks at a faster rate than humans hence increasing throughput.

• Reduced Labor Costs: Minimizing the amount of work that is done by hand can provide substantial savings when applied to palletizing as well.

• Enhanced Safety: This is because most of the workplace injuries that befall employees involve lifting objects that are beyond their capacity.

• Scalability: Another advantage is that palletizing robots are fairly easy to upsize to accommodate increasing calls for products, so firms can easily respond effectively to increased opportunities.

Conclusion

In conclusion, the palletizing robot price varies widely based on several factors, including the type of robot, automation level, load capacity, and geographical location. Businesses looking to invest in palletizing robots must consider their specific needs and budget, whether they are looking for a cost-effective robot for small businesses or a high-end robotic palletizer for large businesses. Investing in the right system can significantly improve operational efficiency, reduce labor costs, and boost productivity in the long run. For more information on robotic palletizer price and how they can improve your business operations, feel free to explore more of our products at Warsonco Robotics.