The Advantages of Flexible Palletizing Robots for Small Businesses and Large Enterprises

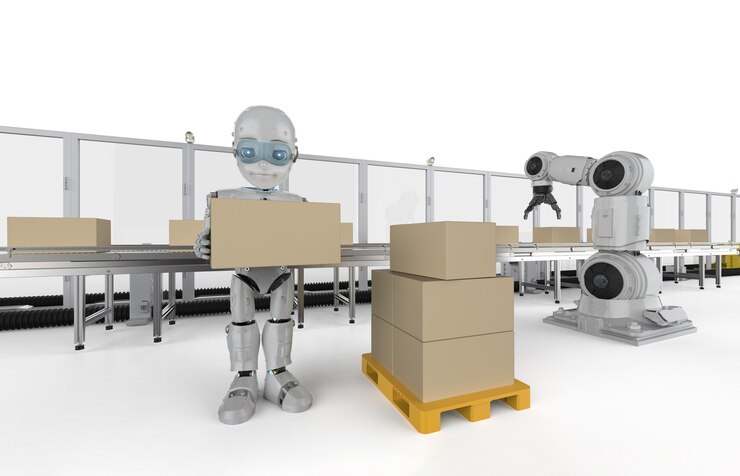

Looking at the new trends of industrial automation, these flexible palletizing robots have made a big difference. These state-of-the-art systems provide unmatched dynamic performance that is flexible and efficient in nature and they find great application in the logistics, manufacturing, and warehousing industries. If you are interested in improving the line speed or cutting down on expenses then, learning more about robotic palletizing or reviewing our information above, may be highly useful to you.

The Introduction of Flexible Palletizing Robots

In the quickly growing areas of manufacturing and materials transportation, there is a never-ending search for how to do everything better and cheaper. Flexible palletizing robots have turned out to be the building block towards the realization of these objectives. One of the best palletizing cobots that portray this technology is the WSC-MD30 Palletizing Cobot from Warsonco Robotics. This advanced solution integrates the use of premium quality robotics together with software programming to provide as much flexibility as expected, minimal employment of the workforce, and ultimate operation productivity. A major feature of the WSC-MD30 is its impressive capacity for implementing fast and accurate sorting and storing of products as well as its stable performance under high pressure.

The WSC-MD30 is designed to accommodate a broad range of palletizing applications, using a patented coordinate robot system, which allows it to work in limited areas. This design is very economical on power consumption and space due to its high degree of structural integration; it is especially applicable on high throughput production lines most especially where block molding machines are used. The flexibility it offers makes it an exceptionally valuable tool in a manufacturing environment for increasing throughput while system footprint and overall process cost remain low.

Uses of Flexible Palletizing Robots

Whenever it concerns the precise and efficient palletizing of non-repetitive, voluminous tasks in different sectors, flexible palletizing robots are almost irreplaceable. Below are some key sectors where these robots play a vital role:

Manufacturing Facilities

Soft palletizing robots in the manufacturing industry run throughout the palletizing processes. These robots can manage multiple product types and configurations; thus, they minimize workers’ physical involvement, which is expensive and isn’t reliable. Through the application of technological tools, they increase production cadence as they improve the manner in which goods are stacked onto pallets in preparation for further processing or transport.

Distribution Centers

As applied to the distribution centers, robotic palletizers facilitate enhanced packaging and stacking of products. In production lines, the robots help create an easy transition from one line to the storage area so that the products are well arranged in the warehouse to be easily accessed for shipment. This versatility makes them suitable to deal with every kind of product size and shape which makes them suited for the various product categories including electronics and packaged goods.

Pharmaceuticals

It will be important that fluid palletizing robots are used in the pharmaceutical industries in order to cater to very sensitive and delicate products from the companies. These robots guarantee that such products as pharmaceuticals are stocked appropriately for safety and to meet policy requirements. Robots used in a single industry embedded great exactitude this sector for treatment without mistake and increase safety level at the line of production.

Advantages of Flexible Palletizing Robots

There are many benefits possible by incorporating flexible palletizing robots into production operations, all of which can contribute to enhancing high performance. Some of the key benefits include:

Better Production Efficiency.

Since flexible palletizing robots can accommodate a large throughput of products, they increase the general efficiency of production. Since it saves time on manpower work and time wasted during downtimes, it gets manufacturers high-efficiency levels.

Improved Material Handling

These robots apply dexterity when handling material, which decreases the effects of scratching throughout the palletizing phase. Due to their flexibility, they can be used in different kinds of product-contacting, from delicate to massive materials.

Reduced Labor Costs

This greatly reduces the amount of manual effort required in cases of flexible palletizing robots hence reducing the cost greatly. These robots work 24/7, and most can deliver ROI within a short span of time since they are productivity machines.

Enhanced Safety

The fact that less human workforce is at risk of performing dangerous jobs, then the relatively twofold palletizing robots are beneficial. These are relatively small systems that are expected to work independently hence limiting human mishaps occurrences.

Space-Saving Solutions

Table 5 Flexible palletizing robots like the WSC-MD30 are designed to fit into narrow aisles to reduce the amount of space required in a factory. Their design bears optimum utility to available space as well as ensuring stable performance.

Why Choose Warsonco Robotics?

At Warsonco Robotics you will understand that each and every business is different. The WSC-MD30 and other palletizing robots in our line of flexible robotic automation systems are built to cover clients in various sectors of agriculture to consumer electronics. Whether your needs are simple to increase palletizing operation or are complex and have to be incorporated into other automation processes, we are ready to help you identify the solution that will be most appropriate.

Our range of robotic automation services offers optimized options for raising production and operational efficacy while decreasing operational expenditures and physical hazards. Being a leader in flexible automation, multi-product palletizing, and customized palletizing Warsonco Robotics is your automation partner for tomorrow.

Where Flexible Palletizing Robots are Headed in the Future?

Finally, the prospects of flexible palletizing robots are promising by the way they look in the near future. As technologies namely robotics and AI advance, then these systems shall further be made more adaptable to a range of higher orders of work capabilities. The advantages of such systems as AI in decision-making or machine learning in combination with real-time analysis will only increase in the future making the systems absolutely crucial for modern logistics automation and warehouse automation.

The main factor that goes towards establishing robotic palletizing systems as the best solution is the pressure that is being exerted by the market for faster and more efficient production processes. Anyone who opts for investing in future trends in palleting solutions shall stand to benefit in the future.

Conclusion

If you're ready to optimize your palletizing operations, visit our website to explore our range of flexible palletizing robots and discover how we can help transform your production line. Warsonco is here to provide the cutting-edge automation solutions you need to stay competitive in today’s fast-moving marketplace. By embracing the power of flexible robots, you can streamline your operations, reduce costs, and position your business for long-term success. Contact us today to learn more about our customizable solutions and get started on your automation journey.