Collaborative Robot Palletizer -WSC-MD40: Flexible, Efficient, and Safe Heavy-Load Automation

Palletizing is an important process in modernized industries so as to enhance the flow of goods as well as their production. As the demand for automation progresses, more versatile Collaborative robot palletizer is becoming the new trend. If you are in manufacturing, logistics, e-commerce, or the F&B industry, it is important to comprehend how cobot palletizing can help your business. This article will discuss the advantages, use cases, and operating principles of collaborative robot palletisers as well as why every modern industrial automation solution must incorporate these extraordinary technologies.

What is a Collaborative Robot Palletizer?

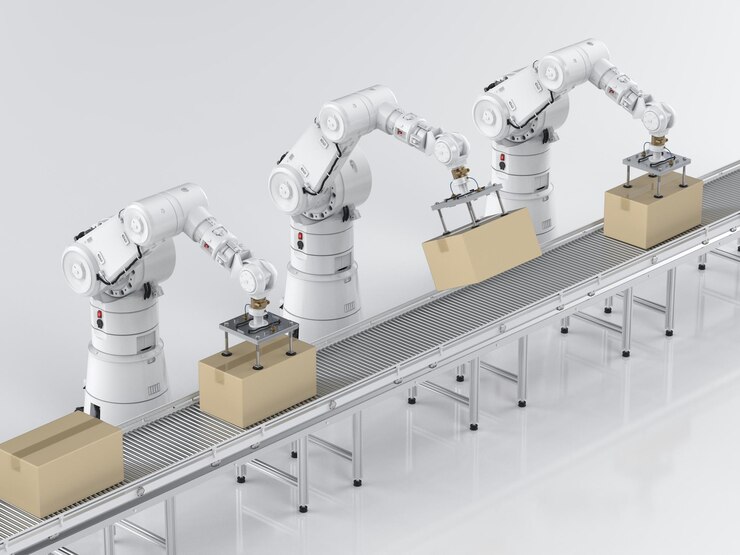

A Collaborative robot palletizer is an advanced automated system meant for palletizing jobs, essentially working alongside human operators. These are designed to complement human employees and therefore bring flexibility, efficiency, and reliability to any operation. While conventional robotic palletizers are generally stationary and perform just one operation and must be completed with safety enclosures, cobots are inherently developed to work with people. It can work with any type of material, size, and weight and is suitable for different industries such as Warehouse automation, logistic automation, and manufacturing automation.

How Does the System of Collaborative Robot Palletizers Function?

Cobot palletizing systems incorporate sensor integration, vision technology, and AI programming to pick products from the floor and place them onto pallets. Such systems are fitted with different types of end effectors that robots use in order to pick products, for instance, vacuum grippers, mechanical claws, and even special tooling.

Some Key Features of Automated Palletizing with Cobots Include:

• Advanced Sensors: These cobots apply sensors and visioning systems to the size, shape, and orientation of products to enable proper positioning on pallets.

• Flexible and Safe: Cobots are shallow and built to navigate in multiple and small environment applications and also easily reprogrammed for various tasks.

• Easy-to-Program: Cobots are not fixed in their operation and can be easily repurposed to suit multiple products and operations without stringent programming knowledge.

Why Cobot Palletizer-WSC-MD40 is Perfect?

The Cobot Palletizer WSC-MD40 is a perfect solution if you’re searching for a reliable heavy-load palletizer that is both innovative and safe. Integrated with I F C H L C R, it is designed for lifting and moving heavy loads; thus, the deformations of the structure are controlled, and reliable operation is guaranteed in harsh conditions.

Key Features:

• Portable Mobile Base: The prepared mobile base provides the possibility for fast changes and movements within the production area, which is highly appreciated in highly variable production processes.

• 7th Axle Lifting Column: This advanced functionality expands robot capability for movements in the vertical plane, providing improved maneuverability and improved palletization rates.

• End Effector: High suction power is matched by a lightweight and easy-to-use end effector, which also minimizes the chance of product drop and maximizes safety and efficiency.

• Large Suction and Anti-Dropping Patented Products: WSC-MD40’s phantom suction technology offers a safer way of palletizing several products without compromising their losses to the palletizing system.

• Card Positioning System: This system reduces product positioning complexity and improves product positioning accuracy and overall operational effectiveness.

• Mechanical Card Positioning System: Made in simplicity this feature ascertains output reliability and ease of operation underlining the ability of Cobot Palletizer as a reasonable and viable solution in palletizing.

These features provide an efficient palletizing automation tool that gives hefty construction, availability of enhanced features, and ergonomically designed control to industries across all sectors.

Advantages of Cobot Palletizers

Increased Efficiency

Through the use of collaborative robot automation, concerned companies can be able to minimize on time spent on physical work hence improving the efficiency of palletizing. These robots tirelessly work for 24 hours without taking time to rest and areas that have embraced the use of these robots have recorded huge gains in working productivity.

Cost Savings

Through cobot integration, large amounts of output can be achieved with minimum wage costs hence the labor cost is considerably cut. Cobots are easy to program and maintain, thus businesses can achieve relatively short payback periods – or ROI.

Enhanced Safety

Conventional palletizing systems pose numerous challenges or have worker input in the form of repetitive operations within dangerous contexts. Collaborative robots for palletizing reduce workplace injuries as well as provide humans with a safer means of handling throughput to enhance their safety at workplaces.

Improved Flexibility

This ready-made outlook of cobots is the reason why they are designed to be flexible. They can be fine-tuned to accomplish various objectives away from their intended use without long periods of inactivity. This makes cobots future-proof because it means that businesses can easily adjust the cobots to meet new production needs instantly.

Key Considerations When Implementing a Collaborative Robot Palletizer

When integrating a cobot palletizing solution, there are several factors to consider to ensure smooth operation:

• Payload Requirements: Select a cobot with enough payload to support the size and weight of objects it will be palleted.

• Space Constraints: A cobot is perfect for a constrained setting, but one needs to evaluate if this consists of the range of motion of the robot.

• Integration with Existing Systems: Make sure that the palletizing application of the collaborative robot, the palletizing system, can easily connect with other kinds of automatic equipment such as conveyors, sorting systems, and other warehouse management and tracking systems.

• Training and Support: Choose a provider that has the correct training and technical support for your workers, so everyone can get the best out of the cobot.

Cobot Safety: An Essential Element in Automation Cooperation

Another aspect that sets a collaborative robot apart from traditional industrial models is that it has its safety mechanisms. Contrary to typical robotic solutions employed in industrial environments, cobots are engineered to interact with their human coworkers without the necessity of shielding the robot against possible harm. Cobot safety features include:

• Collision Detection: Collaborative cobots can recognize cases of contact with people or objects and either halt motion or adapt it to prevent harm.

• Force Limiting: Cobots are designed with force control systems, which set a maximum force that the cobots use, to avoid colliding forces on the worker.

All these safety features are crucial in realizing the feasibility and safety height of human-robot collaboration for palletizing in workplaces.

The Future of Collaborative Robot Palletizers

The future for robotic palletizers exists sustainably especially due to continuing advancements in artificial intelligence, machine learning,g, and robotics. Since these cobots become developed and advanced more than before, they can work in more fields and can provide flexibility and functionality. As we progress in the fields of machine vision, robotic automation, and cloud access, cobots will be able to carry out more varied convincing tasks, including fine operations like picking more fragile items, several-step operations, and signal exchange with other systems.

Conclusion

Collaborative robot palletizers are transforming how businesses approach the palletizing process. Whether you're a small business looking to automate palletizing tasks or a large enterprise seeking efficiency, cobots offer a safe, flexible, and cost-effective solution. With benefits like increased productivity, cost savings, and enhanced safety, collaborative robot automation is the future of palletizing.

To learn more about how cobot palletizing solutions can optimize your operations, visit Warsonco Robot.