-

Search

-

+86 18046987606

[email protected]

Top Benefits of Using a Box Palletizing Robot in Your Production Line

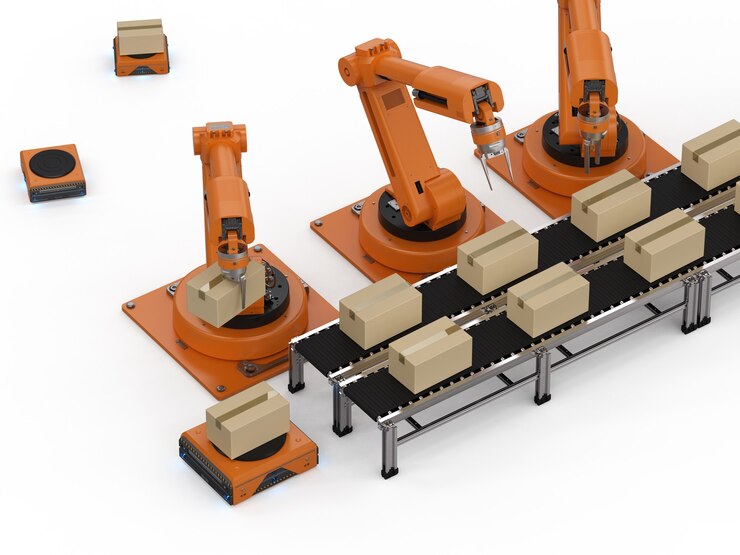

With the present industrialized environment, it is no longer optional to automate, it has become a must. An important type of robot within this area is a box palletizing robot. This innovative technique has impacted almost all sectors with a concentration on logistics, packaging, and warehousing. These indispensable robots from the manufacturing and assembly line to the pharmaceuticals assist in increasing operations productivity to product safety. For you, it may mean that if you deal with such things as material handling or with the improvement of the production line, the knowledge of the worth of palletizing automation will be the crucial factor that will allow you to become the leader in the packaging market.

Palletizing Cobot - WSC-MD30: Industry Outlook of Flexible and Efficient Stacking Solutions

WSC-MD30 Palletizing Cobot is a model that can revolutionize the current production processes with the help of integrating highly developed robotic hardware and software systems. This stacking industry solution was created with flexibility, precision, and compactness in mind and is a game changer for any company attempting to optimize its line of production.

What Sets the WSC-MD30 Apart?

Out of all the products of the WIT Group, the WSC-MD30 is a robotic palletizer designed not only to increase output but also to occupy less space and require fewer workers. Thanks to high speed and excellent stability, it enables manufacturers to meet high-req production requirements in terms of accuracy. As an abstract idea, these cobots are designed to function in different industries and provide maximal performance regardless of the task it accomplishes.

Here’s a Closer Look at the Key Features that Make the WSC-MD30 an Industry Leader:

Patented Coordinate Robot System

The WSC-MD30 incorporates a patented coordinate robot system that controls every motion of the robot as well as improves the performance of its palletizing tasks. This advanced system enables accurate positioning with the added capability of placing the products at accurate positions reducing the probability of making mistakes while stacking the products.

Compact and Space-Saving Design

Measuring 30cm wide, 32.5cm deep, and 6.8cm high, one of the most attractive qualities of the WSC-MD30 is its slimline design, which will easily fit into any confined space. In contrast to typical industrial robot palletizers, this cobot is compact enough to be easily integrated into spaces severely constrained by floor area. This efficient design helps further the abilities of these businesses by making the most of production without the inconvenience of behemoth equipment.

Energy-Efficient Performance

The WSC-MD30 is designed with energy economy in mind which will assist businesses lower their expenses. Given it is capable of handling high throughputs without consuming much power, this palletizing robot enables manufacturers to meet high demands without necessarily learning their power usage or expenses.

Automatic Production Line

Considering its design the WSC-MD30 contributes tremendously to exercising development of the complete block molding machine production line. Thus, by interacting with other equipment in the production process, it is possible to make the latter well-organized and continuous, without the use of heavy manual input.

Advantages of Using the WSC-MD30 in Your Breast Production Line

Reduced Labor Costs:

The WSC-MD30 also boasts automated functions that lessen the reliance on manpower, apart from which also serves to greatly lessen the expense as well as risk to workers due to repetitive and physically demanding operations.

Improved Production Efficiency:

The rapid and accurate operation of the WSC-MD30 leads to an increase in the upturn rate in the manufacturing process as the cycle time of stacking is reduced.

Space Optimization:

The WSC-MD30’s flexibility means it is especially suitable for more confined production areas so that you can make a greater number of animals without occupying too much space.

Seamless Integration:

The cobot is compatible with existing production lines to enable organizations to avoid drastic changes in their operations when adopting the system.

Higher Consistency and Precision:

Wish the WSC-MD30 provides demonstrably high degrees of accuracy such that pallets are loaded evenly on top of one another hence reducing errors that may cause product damage or slow down the production line.

How Does the WSC-MD30 Enhance Manufacturing Flexibility?

This indicates that the WSC-MD30 is also flexible for it can be set to operate under the production needs of a business. From small boxes in a food processing plant to medium-sized boxes used in pharmaceutical productions to intricate patterns in warehouse robotics, this cobot is the perfect material handling addendum any company requires to improve on their material handling.

This feature enables the WSC-MD30 to minimize cycle conversion time for the various palletizing formations, thus enabling manufacturers to perform various tasks at a faster rate without the need for other expensive equipment.

Applications of the WSC-MD30

• Packaging and Logistics: Perfect for production facilities that use large amounts of packaging, including food and pharmaceutical companies, the WSC-MD30 performs best in palletizing boxes for shipment.

• Manufacturing: This is a cobot that uses either first or second-generation robotic technology to handle activities of palletizing; be they large voluminous delicate items or fine and small precision parts, this cobot is efficient in meeting all the requirements of demanding manufacturing equipment providing opportunities for fast and accurate palletizing.

• Warehouse Automation: Due to its maneuverability, the WSC-MD30 optimizes the levels of automation within business warehouses and other storage facilities.

• E-commerce Fulfillment: It seems that the demand for logistics automation increases as the e-commerce industry develops more. The WSC-MD30 enables proper arrangement of products for the packaging of goods enhancing the performance of businesses.

Working Mechanism of a Box Palletizing Robot

The system of automatic box palletizing is based on robotic arms, sensors, and sophisticated software. These robots are equipped with machine vision to measure the size, orientation, and position of boxes. The robot can then grab the box and position it correctly on a pallet depending on a given pattern of how the boxes should be stacked.

The Process Includes Several Steps:

• Box Detection: Barcodes or vision systems simply detect the incoming boxes and their orientation or size for example.

• Box Picking: The robot arm can pick up from the box using suction cups or mechanical grippers depending on what is inside the box.

• Pallet Stacking: To minimize movement, the robot sets the box on a pallet presenting it in an orderly manner to allow for efficient alignment.

Line palletizing automation systems can be controlled to move depending on the type of box in use thus making them very versatile for the various packaging lines.

Selecting the Right Box Palletizing Robot for Your Company

When selecting a box-handling robot, consider the following factors:

• Speed: At what rate do you require the boxes to be palletized? It takes fast robots for industries where production is limited by time.

• Payload Capacity: Check that they have the carrying capacity of your boxes in terms of weight.

• Flexibility: In that case, do the robots support various sizes and shapes of the box? Flexible box palletizing systems can be used depending on the packaging requirements.

• Integration: You should make sure that you choose a robot that can quickly fit into your production line.

With this knowledge, therefore, you will be in a position to select the most appropriate palletizing robot for your business.

Conclusion

A box palletizing robot is not just a piece of equipment—it's a game-changer for industries dealing with packaging, logistics, and manufacturing. These robots improve efficiency, reduce costs, and ensure safety in warehouses and factories. With the ability to handle boxes of all sizes and adapt to different industries, these robots are a key component of the future of industrial automation. Whether you need a flexible box palletizing system for small boxes or a high-speed box palletizing robot for heavy-duty tasks, there's a solution for you. If you’re looking for an advanced box palletizing robot, check out Warsonco Robotics for high-quality solutions tailored to your business needs.